Beverage Can Rinsing

Efficient, Customizable Cleaning System for Cans and Bottles

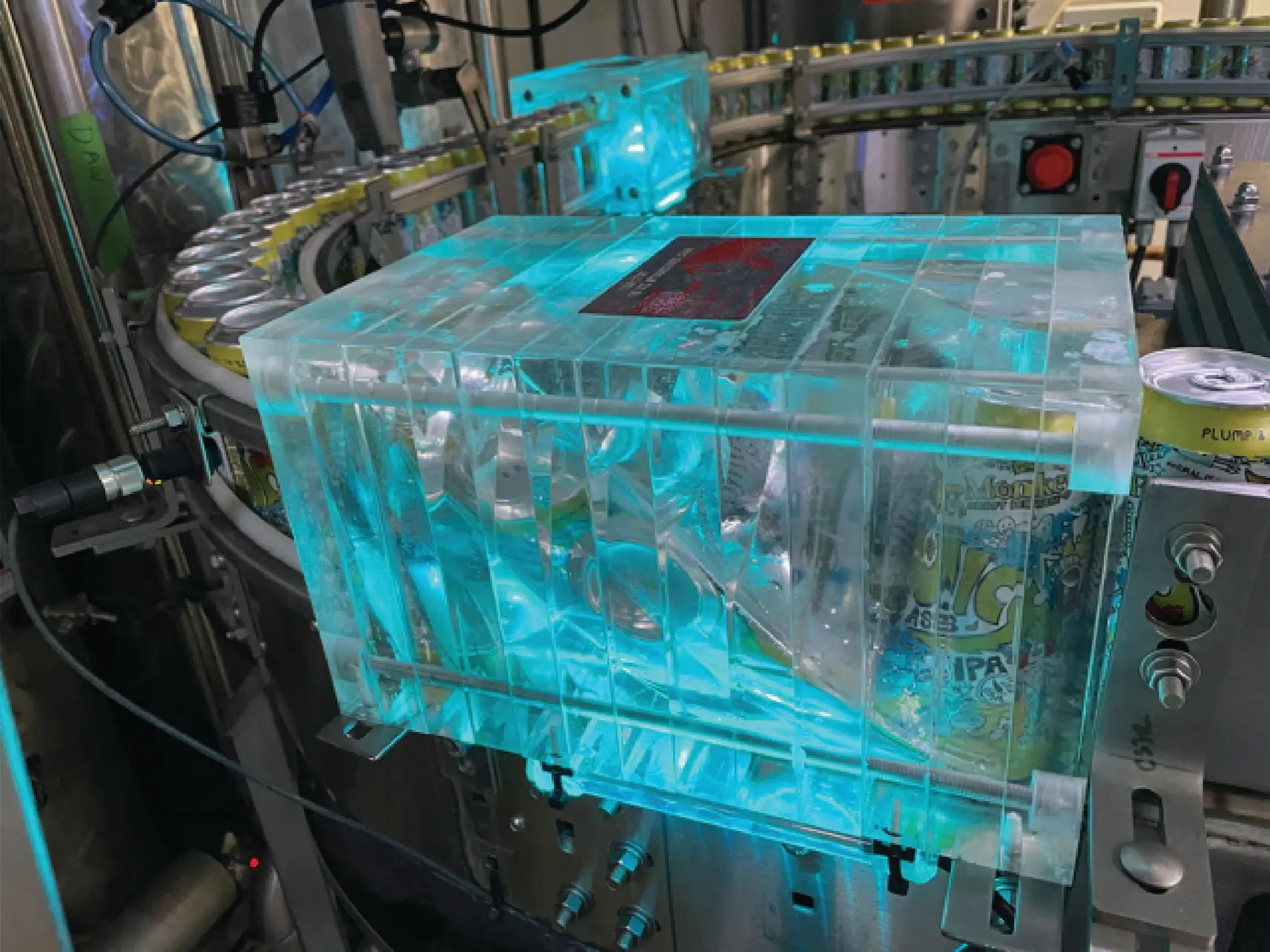

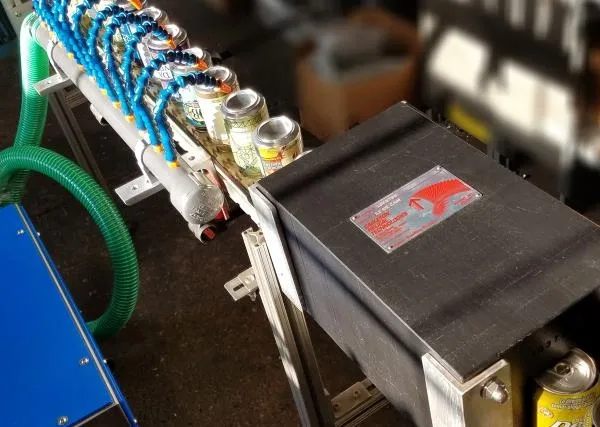

The CHT Can & Bottle Cleaning System is purpose-built for efficient beverage can and bottle rinsing, ensuring containers are clean and contamination-free before filling and labeling. The process begins as cans or bottles enter a CHT Invertor, which smoothly rotates them 180 degrees to an inverted position. From there, the containers are guided through a precision belt drive system that controls their speed as they pass through an ionized air vacuum chamber, removing dust, debris, and static. In the final step, a second CHT Invertor returns the cans or bottles to an upright position, ready to continue through your beverage production line.

- Starting at 10 cans per minute – runs up to 1000+ per minute.

- Customized Invertors and Craft Beverage Cleaning System to the specific size of your cans/bottles.