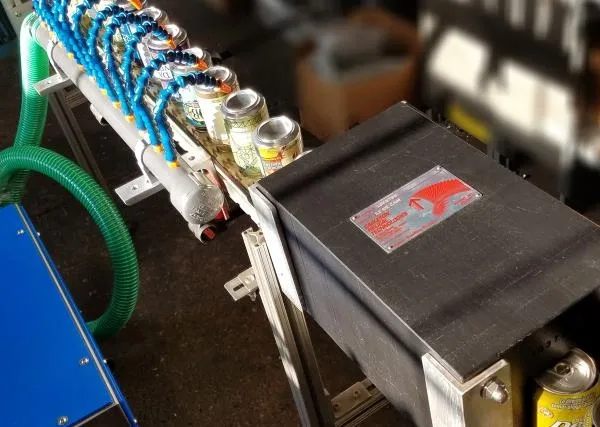

Beer Can Blow-Off System

Targeted Air Cleaning with the CHT Can Blow-Off System

Improve line efficiency and product quality with the CHT Can Blow-Off System—engineered to remove water, debris, or condensation from upright or inverted cans using high-velocity air nozzles.

This system ensures optimal surface conditions for downstream processes, such as date coding, by drying cans prior to inkjet or laser application. It can also be installed post-coding to assist with drying ink, reducing smudging and downtime.

Ideal for high-speed canning lines, the CHT Blow-Off System enhances cleanliness, improves code legibility, and supports regulatory compliance.

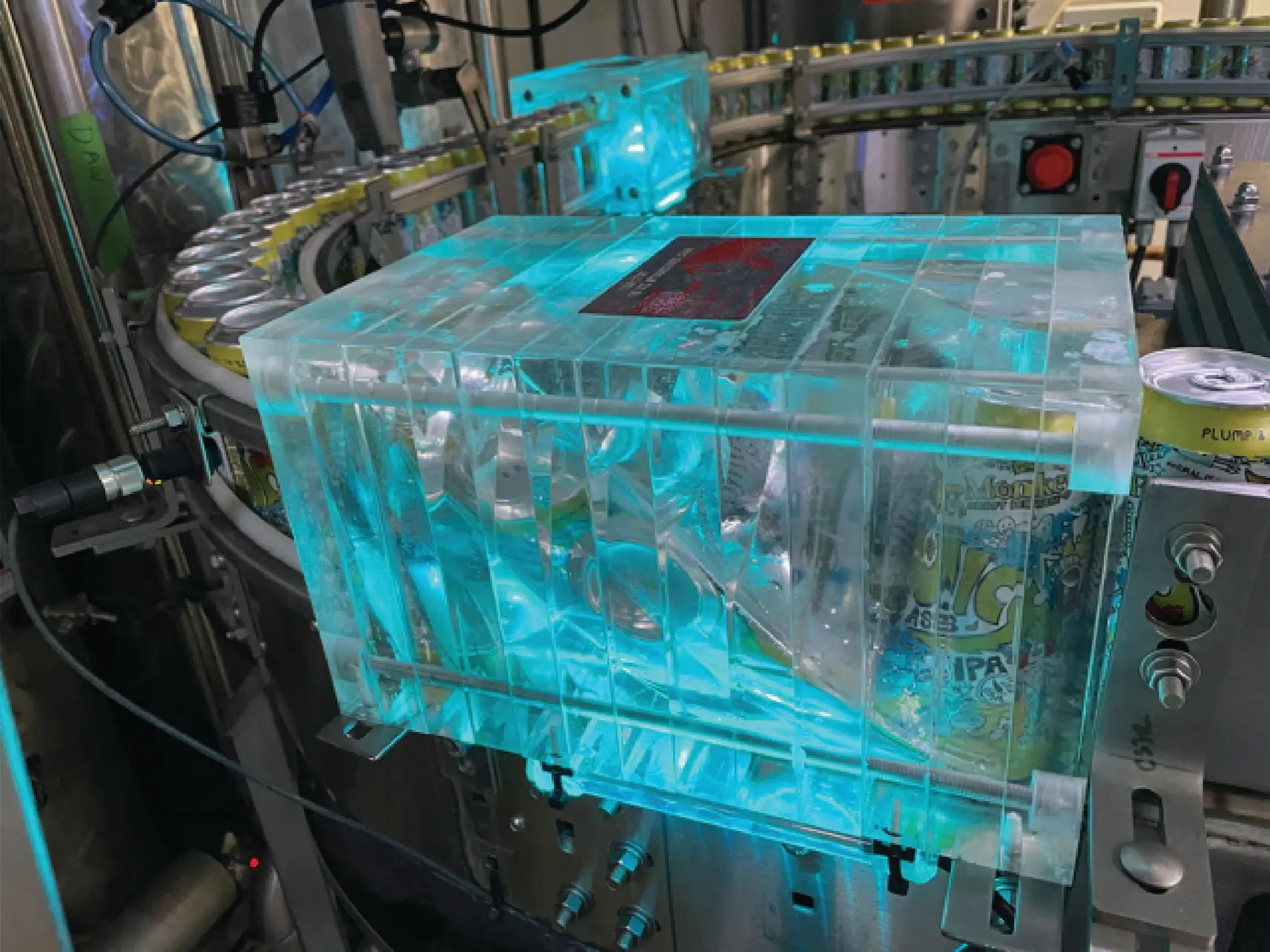

The CHT Can Blow-Off System features a 180-degree can invertor that smoothly inverts containers before passing them under high-powered air blow-off nozzles. Using either back pressure or a precision belt drive system, the cans are guided efficiently through the cleaning and drying process.

After moisture or debris is removed, the system automatically returns the cans to the upright position, preparing them for the next stage of the packaging line—whether that’s date coding, labeling, or filling.