CHT Introduces High-Speed Invertor (Twist Block) for Superior Container Handling Efficiency

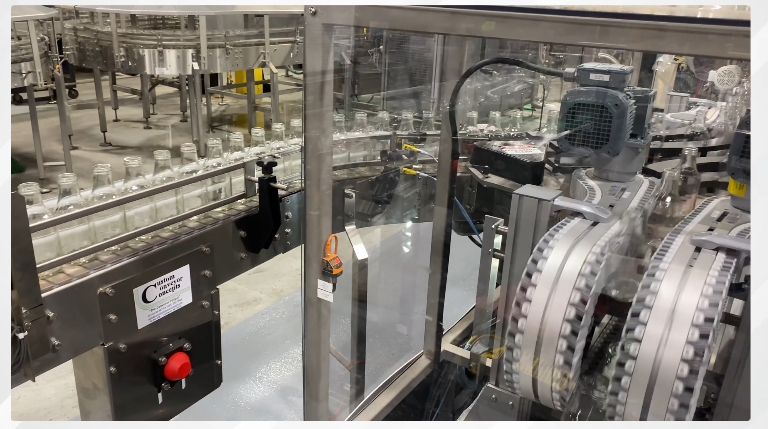

CHT proudly announces the launch of its cutting-edge CHT Invertor, also known as a twist block, an advanced in-line solution designed to rotationally position containers with unmatched speed and precision. Engineered for seamless integration into conveyor systems, the CHT Invertor enhances productivity across a wide range of container handling applications.

Capable of rotating containers 90°, 180°, or 360°, the CHT Invertor enables improved downstream processing, orientation, and handling. Each unit is custom-engineered to accommodate the specific characteristics of the container it services—ensuring maximum efficiency and productivity.

“The CHT Invertor represents a major leap in container handling technology,” said Tanner Cornell, Lead Engineer at CHT. “It combines speed, reliability, and flexibility with a low-maintenance, zero-energy consumption design—making it a smart, sustainable choice for high-volume production environments.”

Key Features & Benefits:

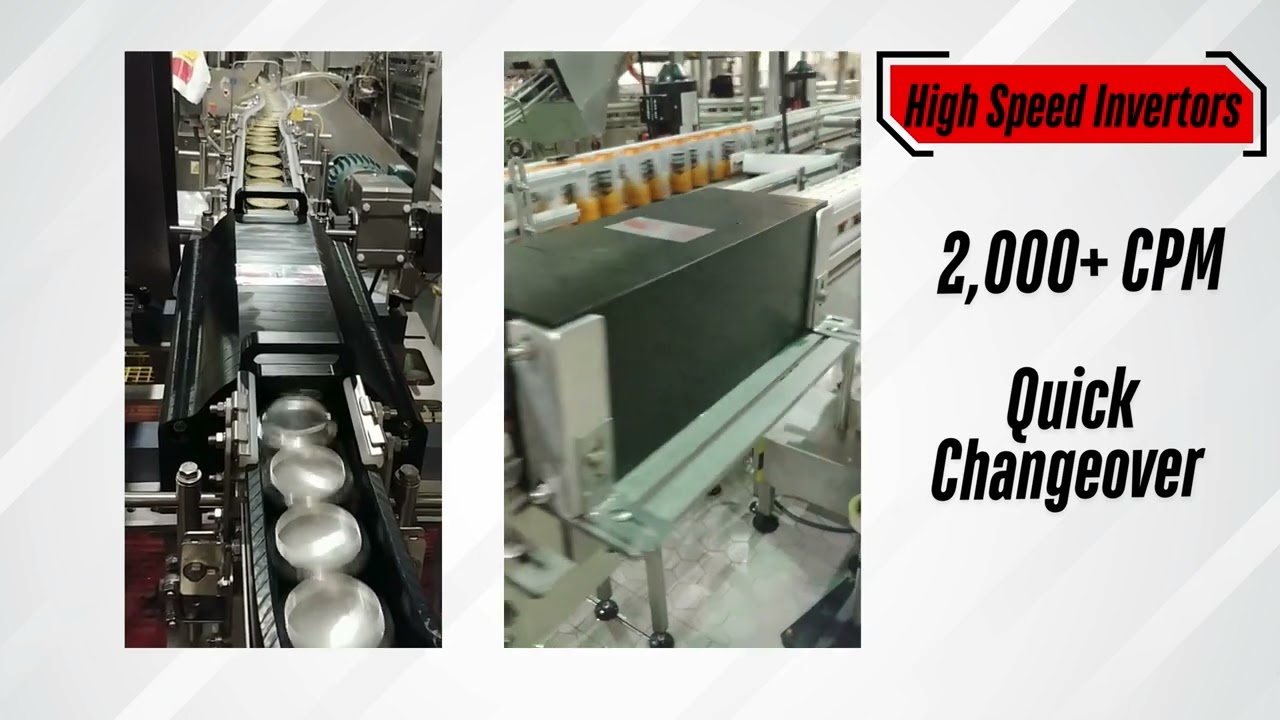

- Ultra High-Speed Rotation: Achieves speeds up to 2,000 containers per minute (CPM), depending on container type.

- Energy-Free Operation: Requires minimal backpressure and no energy consumption, making it an environmentally friendly component.

- Quick Changeover: Designed for fast transitions between container types, minimizing downtime.

- Precision Engineering: Custom-built for each container to optimize handling and reduce product loss or misalignment.

The CHT Invertor is ideal for a variety of applications, including 360-degree product mixing, coding and marking, ionized air rinsing, rotational positioning for downstream processing, cap sterilization and replacing traditional twist rails. It also eliminates the need for rail calibration, reduces space requirements, and enables fast, efficient changeovers—saving both time and resources on the production floor.

The CHT Invertor is also fully integrated into CHT’s Ionized Air Rinsers, allowing for rapid and precise container orientation before the rinsing process. This ensures thorough cleaning and improved overall line performance.

For more information on the CHT Invertor or to request a demo, please contact us below.