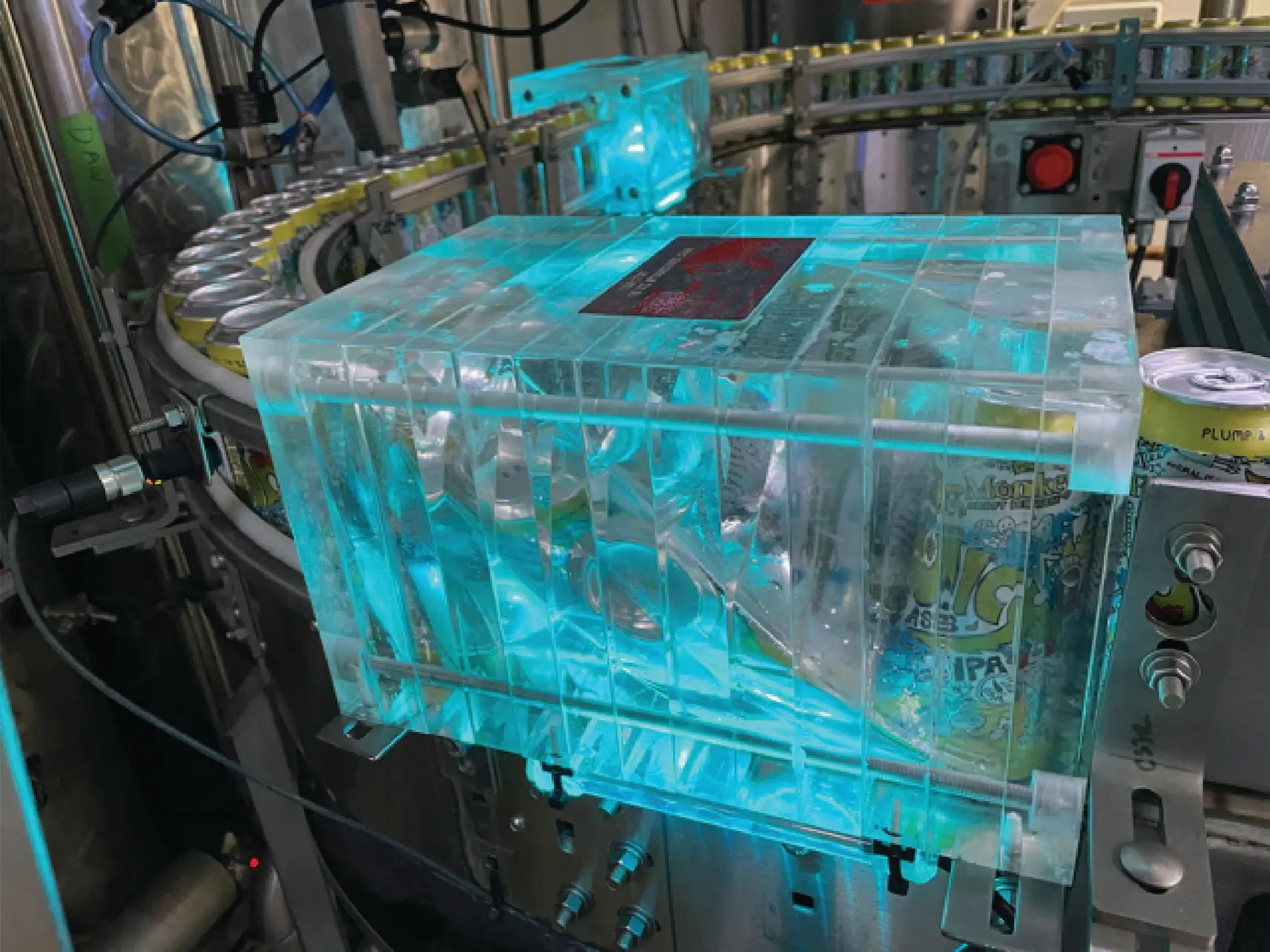

Invertor

High-Speed, Zero-Energy Container Rotation with the CHT Invertor

The CHT Invertor, also known as a twist block, gently and rapidly rotationally positions a variety of containers at high speeds. Invertors or twist blocks allow for swift manipulation of containers anywhere from 90-180-360 degrees to improved handling of containers along a conveyor system. CHT invertor are custom engineered to each specific container for maximum productivity. The integration of our inverting solutions is easily achieved and has quick changeover options.

Invertors are incorporated onto our Ionized Air Rinsers to swiftly position containers before they are air rinsed.

How it works:

Movement of containers through the invertor is a continuous motion and is able to achieve ultra-high speeds (dependent on the container), approximately 2000 containers per minute (CPM). Minimum backpressure is required to move containers through the invertors, thus also making it a zero-energy consumption component.

Utilize the Invertor for these applications:

- Mixing

- Coding

- Ionized Air Rinsing

- Product mixing 360 degrees

- Rotational positioning – for downstream processing

- Replace twist rails

- Eliminates calibration on rails

- Space & time saving – Quick changeover

- Cap sterilization 0-90-0 degree