Ionized Air Rinser & Container Cleaning Solutions

Ionized Air Rinser for Container Cleaning | High-Efficiency In-Line Rinsing System

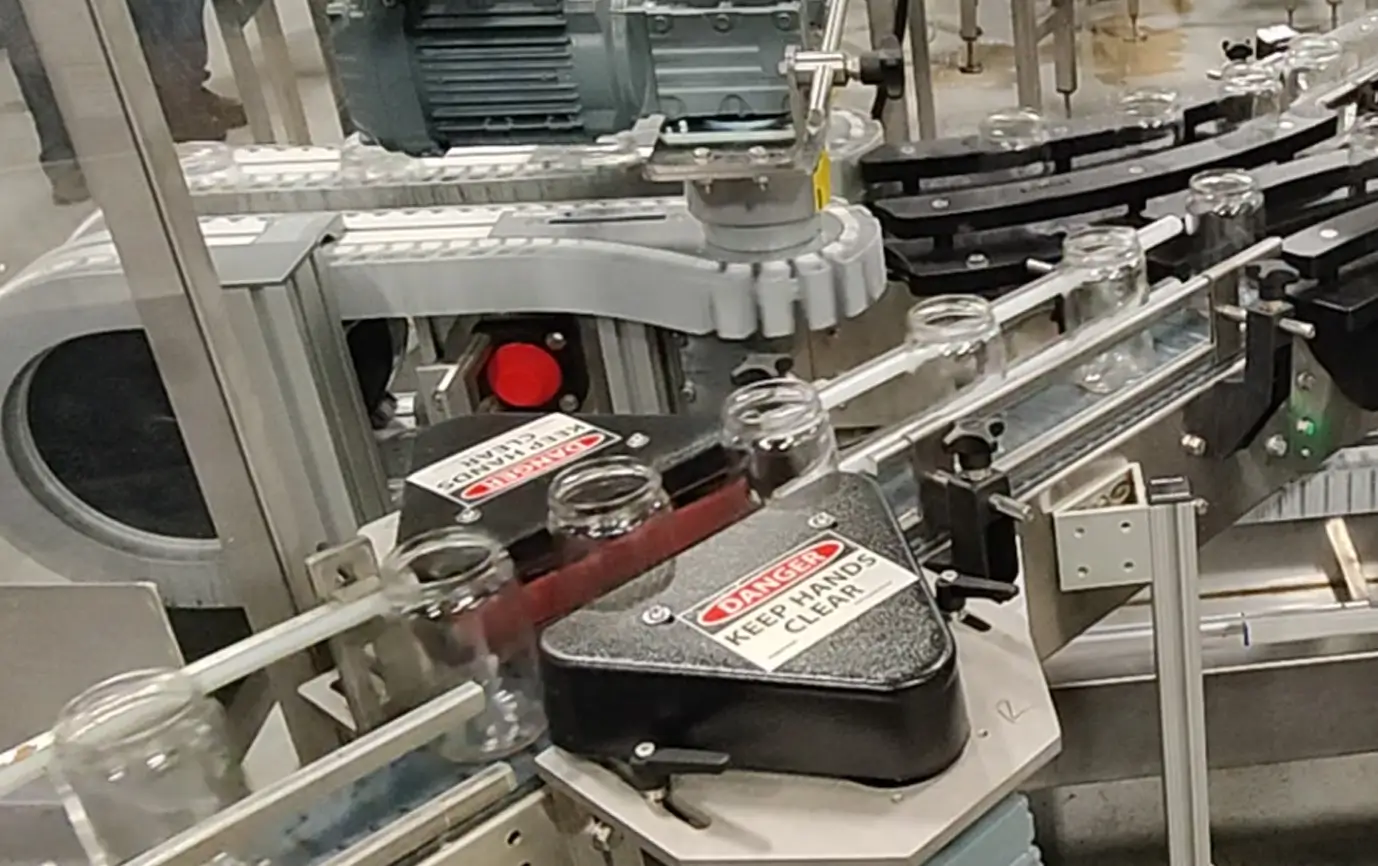

The Ionized Air Rinser is an advanced container cleaning system engineered for high-speed packaging lines. Designed to clean a wide range of container types—glass, plastic, metal, fiber, and more—this air rinsing machine efficiently removes dust, debris, and particulates using ionized air and vacuum technology. Ideal for food, beverage, pharmaceutical, and industrial applications, this in-line rinsing system ensures containers are clean, contaminant-free, and ready for filling.

Key Features of the Ionized Air Rinser

- Efficient Ionized Air Cleaning: Ionized air nozzles generate a positive charge inside and outside the container, detaching debris and pulling it into a high-efficiency vacuum.

- Versatile Container Handling: Supports multiple container shapes and sizes with quick and simple changeovers.

- Durable Construction: Built with stainless steel framing, side panels, and PMMA safety covers for long-lasting durability and protection from debris.

- Advanced Invertor/Revertor System: Containers are rotated over the Ionized Air/Vacuum Assembly for thorough, 360-degree cleaning.

- Clean Compressed Air Supply: Dry, compressed air flows through ionized nozzles to create turbulent air movement for maximum particle removal.

- Vacuum Debris Collection: All debris is collected in a filter canister, with manual disposal options based on usage frequency (daily, weekly, or monthly).

- Customizable Rinsing Options: Choose from ionized air, non-ionized air, water, or custom rinsing solutions based on your application needs.

Technical Specifications

- Dimensions: 72″ L x 36″ W x 48″ H (approx.)

- Speed: Configurable to match conveyor or production line speeds

- Motors: High-performance AC gearmotors

- Electrical: NEMA 4 rated; voltage options available

- Frame: Stainless steel with full protective enclosure

- Optional Add-ons: HP Invertor/Revertor Assembly, washdown-compatible units

- Maintenance Parts: Filter bags, belt pulleys

Made in the USA