MLC Rinsing Solutions

MLC Rinser

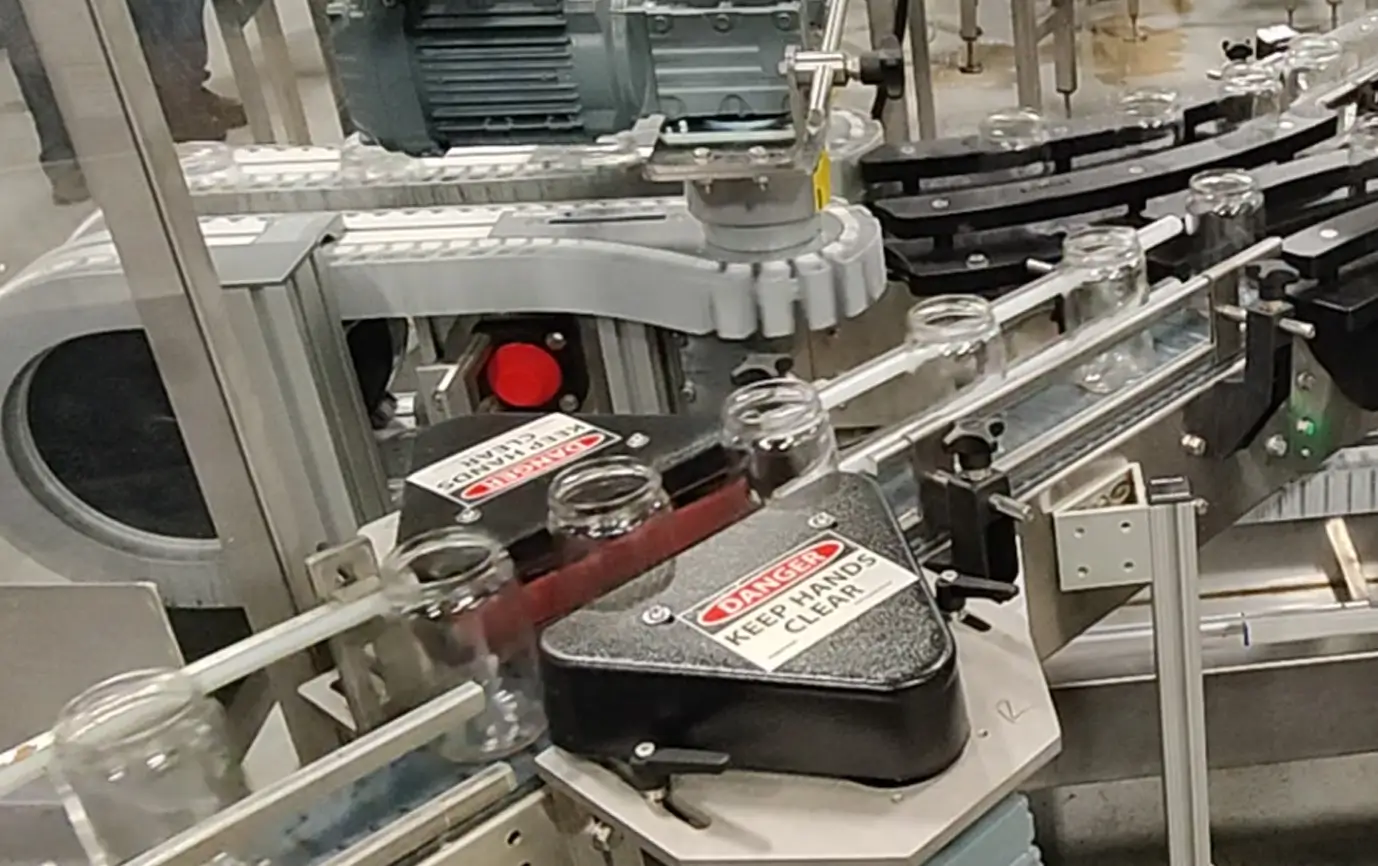

Elevate your packaging operations with the cutting-edge MLC (Multilane Linear Changeover) Air Rinsing Solution from Carleton Helical Technologies. Designed for precision and customization, this rinser boasts innovative quick changeover capabilities that cater to lines handling multiple container sizes, prioritizing time-saving solutions for busy production environments.

Key Features of the MLC Rinser

The standout feature of this rinser is its integrated changeover system, seamlessly built onto the stainless-steel frame. This system not only ensures line safety by simplifying the changeover process, but also maximizes space utilization by eliminating the need for additional storage. With the multi-lane Invertor System remaining on the ionized air rinser, production line technicians can effortlessly switch between containers, saving valuable time and streamlining operations.

Experience unmatched efficiency and convenience as technicians can swiftly slide one container size to the side and position the next container size, without the hassle of relocating changeover parts. This seamless transition directly on the rinser enhances workflow productivity and minimizes downtime, aligning perfectly with Carleton Helical Technologies’ commitment to delivering tailored solutions for the packaging industry. Check out the feature article at ProFood World.

Technical Specifications

- L x W x H – dependent on container

- Speeds – vary to match conveyor/production line speeds

- Motors – AC Gearmotors

- Maintenance Parts– filter bags, belt pulleys

- Frame – stainless steel, with protective covering

- Electrical – NEMA 4, voltage may vary