FG Ionized Air Rinsing & Cap Sterilizer Solutions

FG Ionized Air Rinser & Cap Sterilizer | High-Speed Inline Bottle and Cap Cleaning System

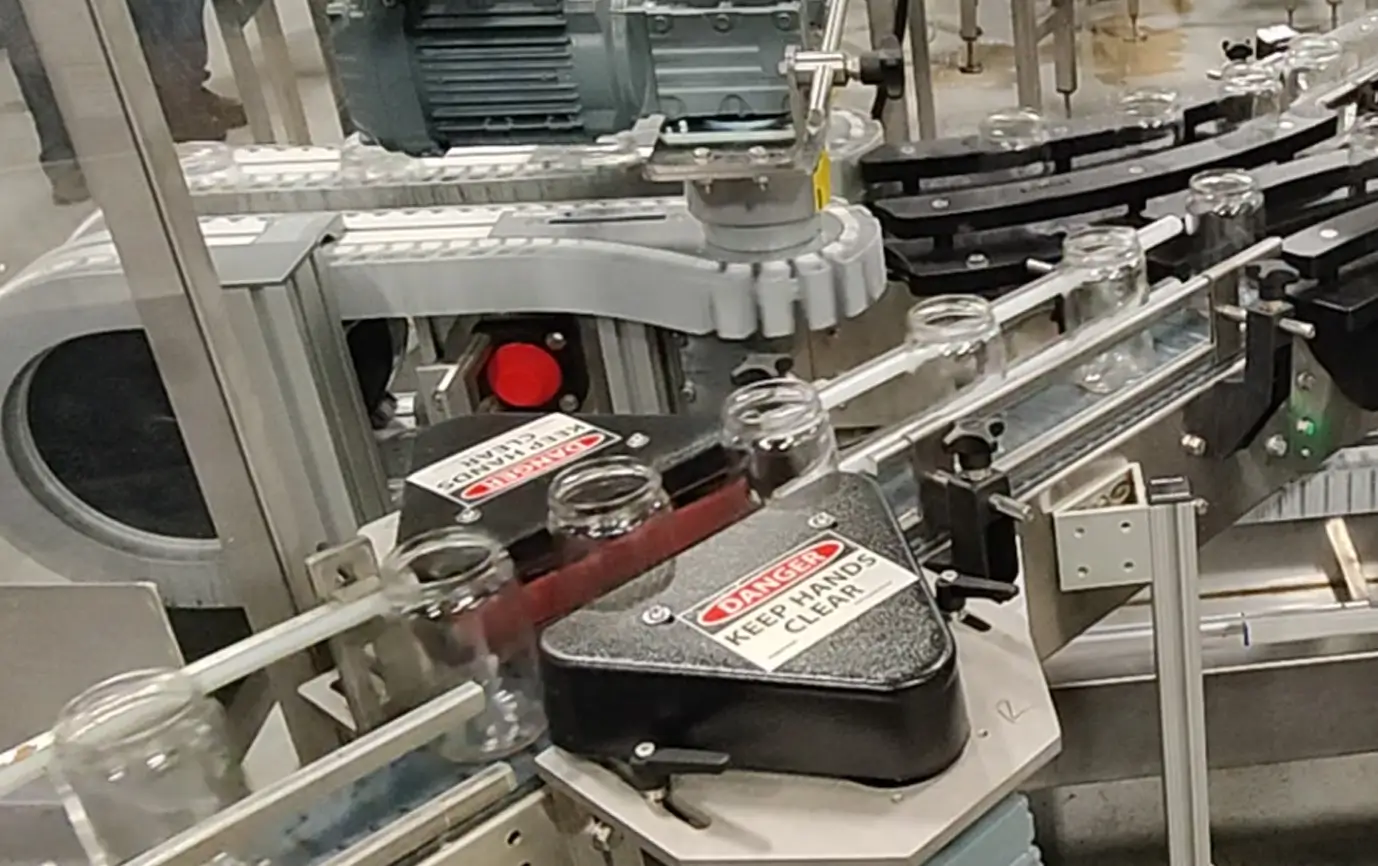

The FG Ionized Air Rinser and Cap Sterilizer is a high-efficiency container cleaning solution engineered for inline production lines. Designed to clean and sterilize bottles, jars, caps, cans, and other containers, this automated rinsing system grips, inverts, and blasts containers with ionized air to remove dust, debris, and static before reintroducing them to the conveyor.

Ideal for packaging lines that require parallel cleaning to the conveyor flow, the FG Rinser ensures precision, speed, and sanitation across a wide range of container types.

Key Features of the FG Ionized Air Rinser

- Parallel Conveyor Cleaning: Designed for production lines requiring inline, synchronized cleaning without disrupting flow.

- Automated Counting and Control: Photo-eye sensor counts containers while belt drives regulate entry into the rinsing station.

- Precision Rinsing Process: Dual pressurized arms grip and invert each container for ionized air cleaning, then return it to the conveyor.

- Customizable Solutions: Each FG Rinser can be tailored to various container sizes and shapes, with fast changeovers for multi-product lines.

- Ionized Air Sterilization: Ionized nozzles neutralize static and detach contaminants, ensuring clean, debris-free containers and caps.

- Built By CHT – Specialist in Air Rinsing Technology: As a leading air rinsing manufacturer, CHT engineers and manufactures all equipment in-house. Our rinsing systems are fully customizable to meet unique container specifications across industries like food, beverage, pharmaceutical, and personal care.

Technical Specifications

- Dimensions: 130″ L x 45″ W x (Conveyor Height + 36″) H

- Speed: Dependent on container and conveyor requirements

- Motors: AC gearmotors and/or servo motors

- Electrical: NEMA 4 rated; voltage customizable

- Frame: Modular aluminum and stainless steel construction

- Optional Add-ons: Multi-size changeover kits, washdown-compatible units

- Maintenance Parts: Filter bags, belt pulleys