Gripper Ionized Air Rinser Solutions

Gripper Rinser: Ionized Air Rinsing for PET, Glass, Aluminum & More

Maximize production efficiency with advanced ionized air technology for clean, contaminant-free PET, glass and more containers.

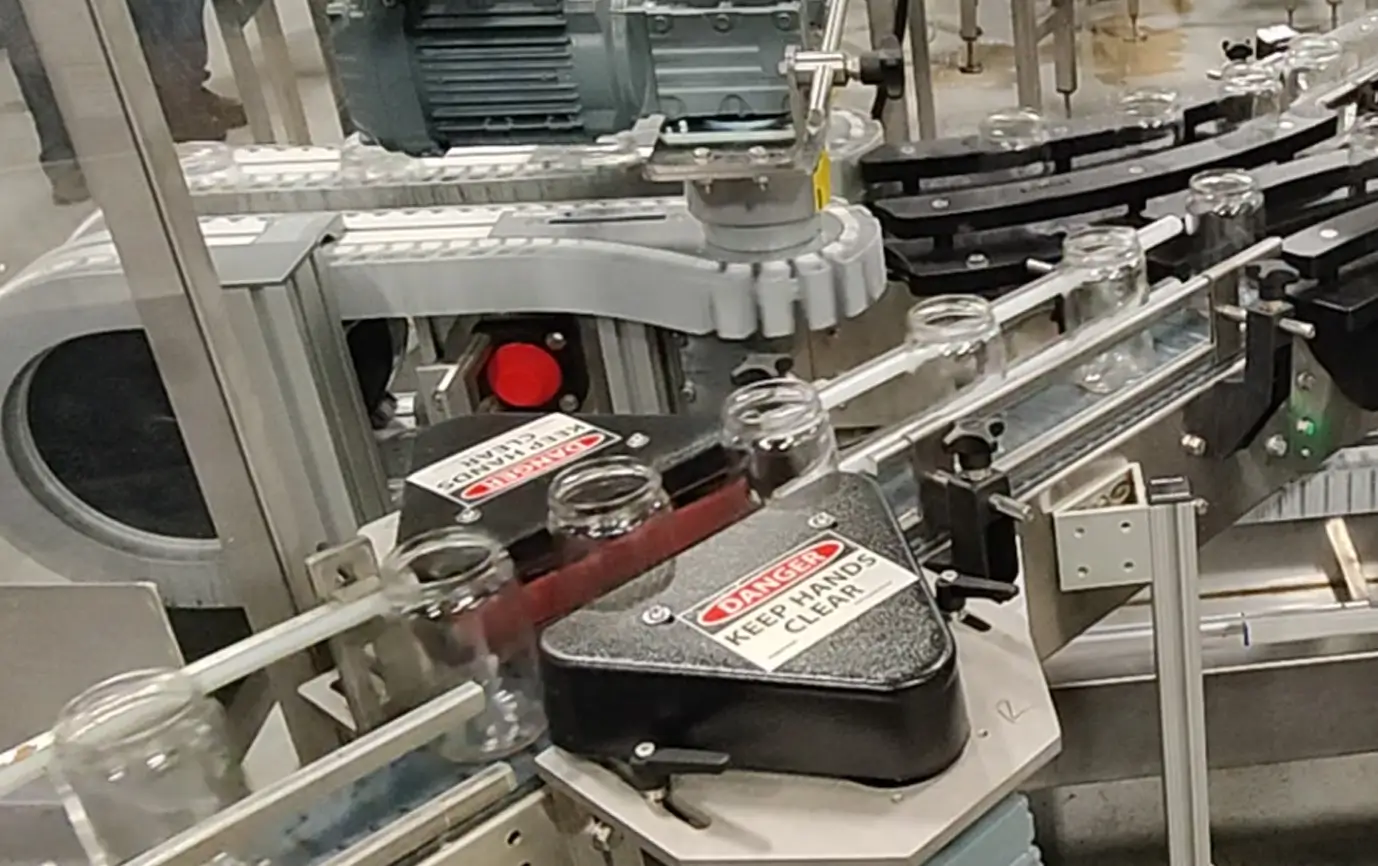

Carleton Helical Technologies proudly introduces the Gripper Rinser, a high-performance ionized air rinsing system designed for versatile container cleaning on today’s fast-paced packaging lines. Engineered to handle PET bottles, glass containers, aluminum cans, and more, the Gripper Rinser provides efficient, waterless cleaning with unmatched speed and precision.

This high-speed container rinser is ideal for manufacturers running multiple SKUs and container materials. It uses ionized air to remove dust, debris, and static, eliminating the need for water or additional drying equipment—perfect for facilities seeking sustainable, low-maintenance solutions.

“With today’s production lines handling a variety of packaging formats, manufacturers need flexibility without sacrificing speed,” said Nick Carleton, President at Carleton Helical Technologies. “The Gripper Rinser delivers reliable, efficient rinsing for any container type.”

Key Features of the Gripper Rinser:

-

Compatible with PET, glass, aluminum, and custom containers

-

Ionized air cleaning removes particulates without moisture

-

Tool-free, fast changeovers reduce downtime

-

Compact footprint for easy integration into existing systems

-

Perfect for high-speed, multi-format production environments

Key Benefits of the Gripper Rinser

- Advanced Ionized Air Cleaning: Uses high-velocity ionized air technology to remove dust, particles, and static from both the interior and exterior of containers.

- Inline Cleaning Integration: Designed to seamlessly fit into existing production and packaging workflows, ensuring containers are thoroughly cleaned before filling.

- Enhanced Productivity: Engineered for high-speed container handling, this air rinsing solution increases line efficiency and reliability.

Technical Specifications

- Dimensions: 120″ L x 54″ W x 72″ H

- Speed Range: 100–500 containers per minute (CPM)

- Motors: 730/460 AC inverter-duty motors

- Electrical Rating: NEMA 4 / NEMA 4X compliant

- Frame Construction: Stainless steel and modular aluminum

- Compatible Container Sizes: 2″–6″ diameter, 4″–8″ tall

- Optional Add-Ons: Belt drive integration

Why Choose CHT

As a leading manufacturer of air rinsing solutions, Carleton Helical Technologies delivers custom-engineered equipment tailored to your production requirements. The Gripper Rinser reflects our commitment to innovation, cleanliness, and long-term performance across a range of industries including food, beverage, personal care, and pharmaceuticals.

Get Started

Connect with our team at Carleton Helical Technologies to discuss how the Gripper Rinser can be custom-fit to your container cleaning needs. Let us help you optimize your production line with cutting-edge air rinsing technology that drives both cleanliness and efficiency.

Gripper Ionized Air Rinser Demonstration | Cleaning Glass Jars of Various Sizes

This video highlights the Gripper Rinser by Carleton Helical Technologies as it efficiently handles and cleans various sizes of glass jars using advanced ionized air rinsing technology. Watch how this inline rinsing system ensures debris-free containers, ideal for packaging applications requiring consistent cleanliness and precision.

Explore Our Full Range of Ionized Air Rinsing Systems | Versatile Solutions for Every Container Type

Check out our full range of air rinsing solutions, including various styles designed to clean bottles, jars, containers, and lids with precision. From gripper rinsers to inline ionized air systems, discover how Carleton Helical Technologies offers customizable rinsers to meet your unique packaging line needs.